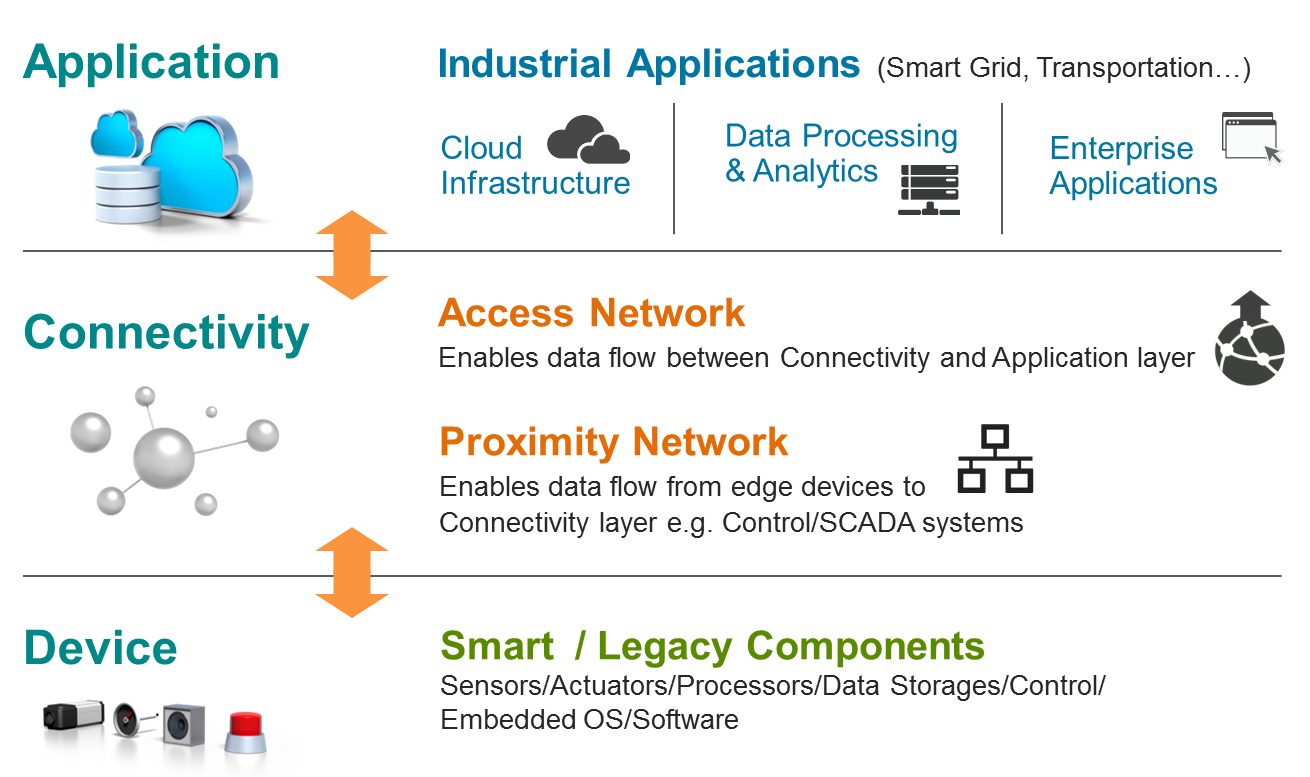

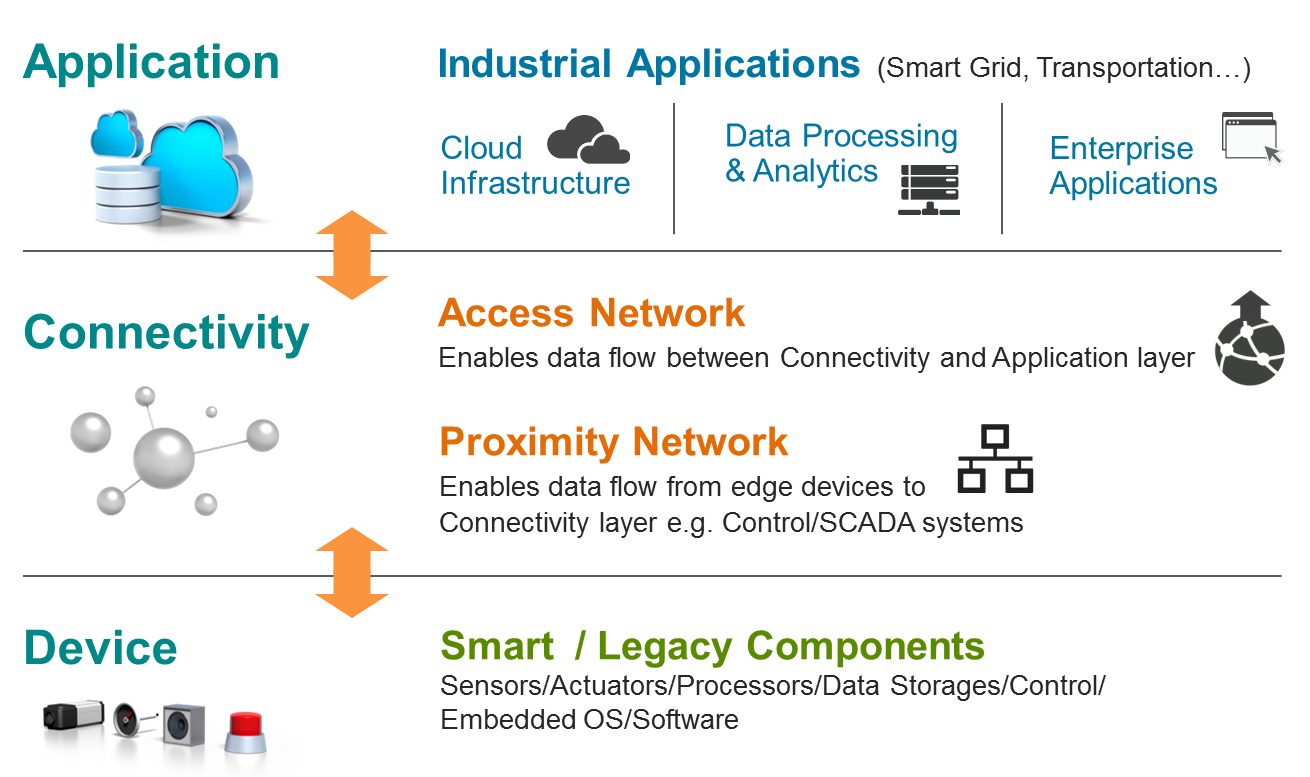

Understanding the Layers of the IIoT

By now, you should have a good understanding of what the Industrial IoT is and the massive benefits that it can bring to operations. Now let’s take it a step further and understand how an IoT network functions. In typical scenarios, there are three layers involved in enabling the Industrial Internet of Things.

Device Layer

The device layer consists of the physical devices (or things) involved in an industrial operation. Equipment, sensors, actuators, processors, controllers etc. These can also be referred to as “edge devices” which indicates that they reside on the edge of the industrial network.

Within the device layer, there can be smart devices and legacy devices. Smart devices are newer and have built-in networking capabilities typically with an Ethernet interface. Legacy devices generally are older, do not have networking capabilities, and usually connect through a serial interface. All of the devices within an industrial operation hold the key to the IIoT, data. The challenge and the sole intent of the IIoT is enabling the use of this data.

Connectivity Layer

The purpose of the connectivity layer is to enable direct connections between devices to extract and transmit the data to an access network. As mentioned above, there can be an abundance of smart and legacy devices within an operation that have different connection interfaces and to add to the complexity, there is rarely a common machine language (or protocol) that all of these devices speak in. The connectivity layer brings everything together and enables communication and data transmission between devices. Of the connectivity layer there are two main networks that work together.

- The Proximity Network enables the data flow from the edge devices to the connectivity layer. This is essentially the network that extracts the data from the devices.

- The Access Network enables the data flow (transmission) between the connectivity and application layer.

Application Layer

The application layer is where the power of the Industrial IoT comes into play. It typically comprises of a central data repository, data processing and analytics, as well as front end enterprise applications.

The central data repository, which is typically a cloud infrastructure, is the platform where device data or “big data” is stored, processed and analyzed for specific applications. From the data repository, there is typically enterprise front end software linked to the data repository that enables users to access applications, rules, and much more. It is within the application layer that many of the end use capabilities of the Industrial IoT are illustrated. Predictive maintenance, remote monitoring and deeper performance insights are just a few capabilities to mention.

Proper Connectivity is Critical for Interoperability

When looking at the layers of the IIoT at a high level, one that usually gets the most attention is the application layer. While the application layer does enable the end use capabilities, the layer that is crucial and often overlooked is the connectivity layer. One could have excellent data sources (devices) and great software and applications to analyze device data, but the extraction and transmission of the data between the two is not possible without enabling connectivity.

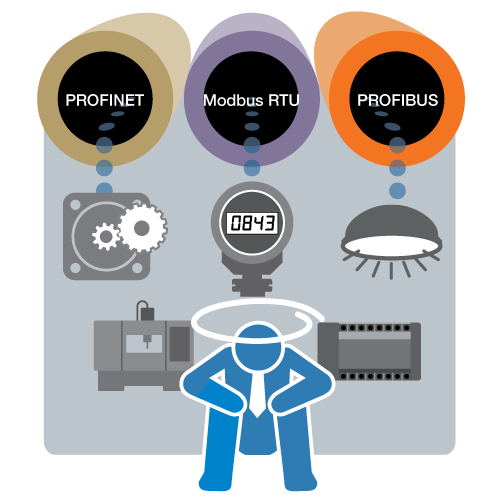

One of the main barriers that many have when trying to connect their industrial operations to the IIoT is being able to achieve connectivity and interoperability between their devices.

Connecting the plant floor, or field network, has long been a topic of concern between industrial network managers and enterprise IT engineers alike. The Industrial IoT relies on the ability for devices to send and receive data into the cloud and between systems. Without interoperability between devices, this is not possible. This means that all devices should speak a common protocol (databus) and utilize the same interface for data transmission. As we mentioned above, most industrial operations can comprise of many different smart and legacy equipment and sensors that have different protocols and interfaces that seem difficult to configure and integrate.

So how does one achieve interoperability?

Making these connections is often perceived to be too costly or complicated but it’s not as difficult as it seems. There are solutions available to convert physical interfaces and protocols to a common configuration for industrial networking.

Making these connections is often perceived to be too costly or complicated but it’s not as difficult as it seems. There are solutions available to convert physical interfaces and protocols to a common configuration for industrial networking.

When connecting devices to the Industrial Internet of things, some of the most common interfaces used to connect devices to the application layer are Ethernet and wireless. When looking at a typical industrial operation, the reality is that not all devices may utilize these interfaces for communicating.

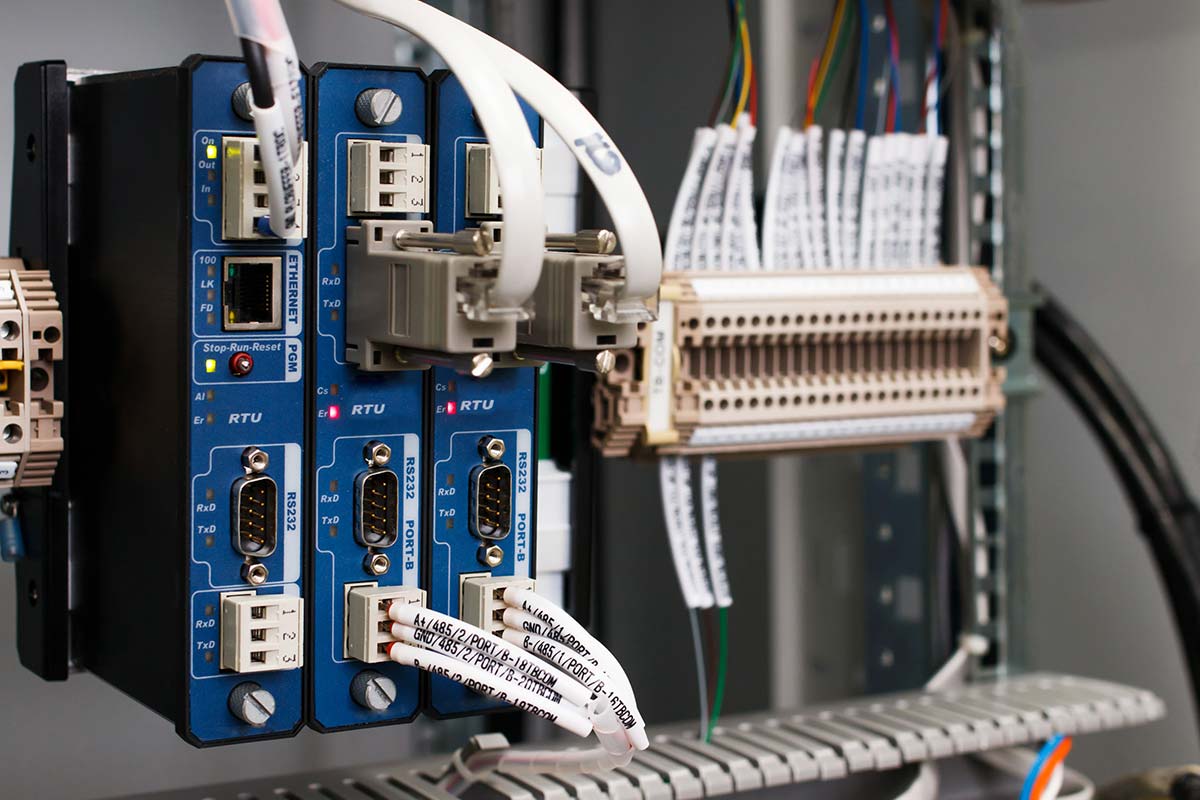

As mentioned earlier, most legacy or older industrial devices communicate via serial and do not come equipped with Ethernet ports or wireless capabilities. That is where device servers can come into play. As an example, a serial device server connects to a serial based device and converts the interface to Ethernet or wireless depending on the model you use. By utilizing a device server, you can extract the data from your equipment and sensors through Ethernet or wireless connections that were not possible before.

Once a common interface is established in an industrial operation, there is one additional step required to enable connectivity to the IIoT. This step is establishing a common protocol or language amongst all the devices. For instance, all devices may have an Ethernet interface, but they may be communicating in different protocols. To remedy this, an Ethernet gateway could be used to convert all protocols to a common protocol. Ethernet gateways are extremely flexible and offer a pain free protocol conversion to suit the demanding needs of industrial networking.

If you would like to learn more about the details behind the connectivity layer, check out our whitepaper: Hands-On Advice For Your First Step Towards IIoT Connectivity

If you are interested in learning more about the Industrial Internet of Things, let us know and we can have one of our representatives will reach out to you with more information.

Want more info like this?

Subscribe to learn more about the IIoT and Industrial Networking.