The Challenge

Tech Manufacturing, a long-time manufacturer of machined metal parts, needed to raise production capacity and reduce lead times for their clients’ largest and most urgent orders. What could they do? Their 5-axis CNC machines were already running 24 hours a day, 7 days a week.

The Solution

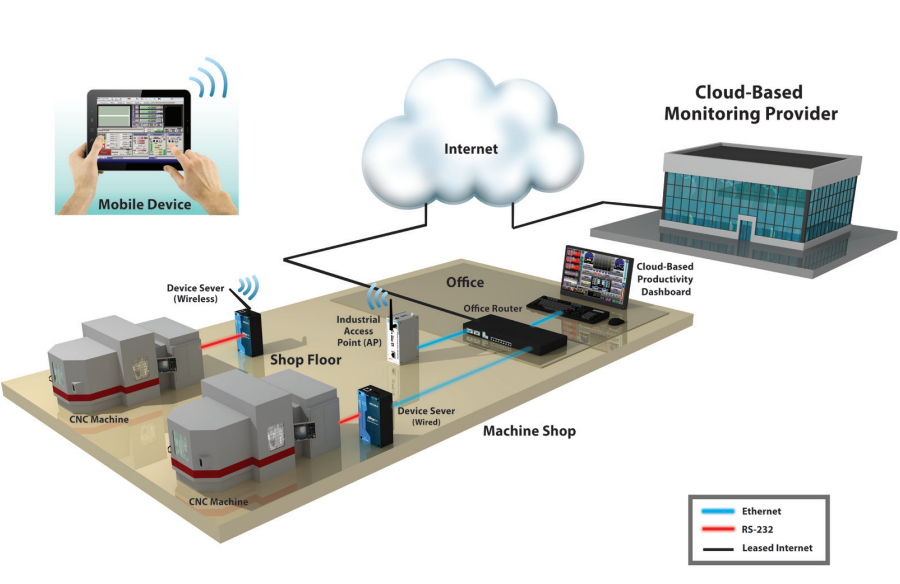

Tech Manufacturing had to get connected. Using simple, off-the-shelf equipment, they connected their existing CNC machines to the local area network. Legacy machines that didn’t have an available Ethernet port were linked via affordable industrial connectivity units from Moxa. Wireless device servers were used to connect RS-232 ports directly over Wi-Fi, allowing for data to be transferred from the ports straight to the office network. All of this combined to extend the life and capabilities of Tech Manufacturing’s older, but still functional, machines.

Highlights

|

The Results

In less than one day, Tech Manufacturing set up a cloud-based CNC monitoring system without any additional IT infrastructure or maintenance effort. They significantly increased productivity and extended the life of their older CNC machines.

By connecting these existing machines to a cloud-based platform, Tech Manufacturing was able to identify critical productivity issues and take the necessary steps to correct them, with very little downtime, maintenance, or additional costs.

Case Study Details

Location: USA

Related Products:

RS-232/422/485 serial device servers

NPort W2000A Series

Serial-to-Wi-Fi device servers

EDS-400A Series

Managed Ethernet switches