The right networking equipment can reduce downtime.

Industrial systems are especially sensitive to downtime caused by network issues. Time is money, and a minute offline can mean thousands of dollars in potential losses, if not more. For mission-critical systems, the stakes can be even higher and may involve public safety. To help minimize the chances of experiencing a significant downtime event, here are some key attributes that industrial users can look for in their networking equipment.

Industrial Design

All networking devices are not created equal.

Ethernet switches, routers, and serial devices have been used in commercial or enterprise applications for many years. Slowly but surely, this networking technology has migrated into industrial systems. This trend is only going to accelerate with the Internet of Things (IoT) movement. However, communications technology that was originally designed for commercial use needs to be adapted for industrial users. One of the most notable differences is in the design and build quality of the networking components:

- Industrial networking equipment should have a high mean time between failures (MTBF). This is a useful point of reference for how long a piece of equipment is designed to operate without failing. MTBF for industrial-grade equipment should be much higher than for commercial-grade equipment.

- Industrial networking equipment should be designed to dissipate heat on their own without the need for built-in or additional cooling fans. This isn’t a critical issue for commercial-grade equipment that is installed in temperature controlled environments, but it can be a major contributor to downtime in industrial settings.

- Industrial networking equipment should have extra protection from electromagnetic and RF interference and surges. Because these devices are typically installed in harsh environments with other machines, it’s important that they are guarded from sudden spikes in power. Surge protection can be built into the networking device or connected via surge protector.

Connection Redundancy

Do you have a backup communication plan?

Communication redundancy provides a backup data transmission route in the event that a cable is inadvertently disconnected or damaged. This can be achieved through redundant rings in the network. Redundancy is a particularly important feature for industrial applications since it can be very difficult and time-consuming to locate and replace a disconnected or severed cable. When looking at the specifications of Ethernet switches, be sure to note the details of redundancy recovery times. A specified recovery time may be achievable for smaller networks but not for larger networks. For example, Moxa’s Turbo Ring technology has been tested to recover from link failures in under 20 milliseconds in a network of 250 switches.

Dual Power Inputs

A power supply is a common point for failure.

Similar to Ethernet redundancy, power redundancy allows for uninterrupted operation in the event the primary power supply fails. Networking equipment can support power redundancy with dual power inputs. If both a DC terminal block input and a DC power jack input are offered, this allows greater flexibility for different applications. In addition to dual power capabilities, it’s also important to look for equipment with isolated power inputs. This extra layer of protection shields against unexpected inrush current that may degrade or completely decommission networking devices.

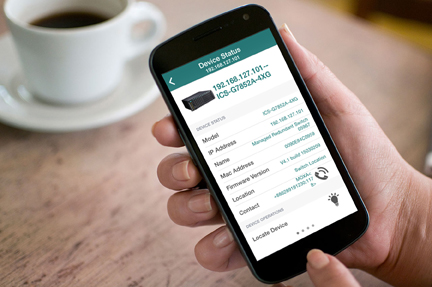

Real-Time Alerts

Minimize downtime with real-time alerts.

As predictive maintenance (PdM) techniques are designed into a network, engineers should be alerted when action is required to recover the network or prevent it from going down in the first place. There are several ways that networking equipment can provide real-time notification to industrial users. Relay outputs on the device can provide immediate notification of abnormal conditions that can potentially impact the network. SNMP traps can also be set up to deliver system notifications over the network. Network management software and tools are also available that make it easy for engineers to monitor every network device and link. All methods reduce downtime by bringing attention to issues that need to be addressed.

NOTE: Be mindful of the number of alerts that your system generates. You can configure the notifications to avoid an overload of alerts to system managers by filtering only the important instances.

When trying to avoid downtime, device reliability is what it boils down to. Pay attention to the most important characteristics of your industrial networking devices in order to increase the reliability of your system. The more protection each component of your industrial network has, the less you’ll have to worry about unexpected failures.

When trying to avoid downtime, device reliability is what it boils down to. Pay attention to the most important characteristics of your industrial networking devices in order to increase the reliability of your system. The more protection each component of your industrial network has, the less you’ll have to worry about unexpected failures.

Have a question about this topic? We would love to hear from you. Please feel free to contact us and one of our representatives will reach out to you with more information.