Moxa’s Ignition-ready Computers

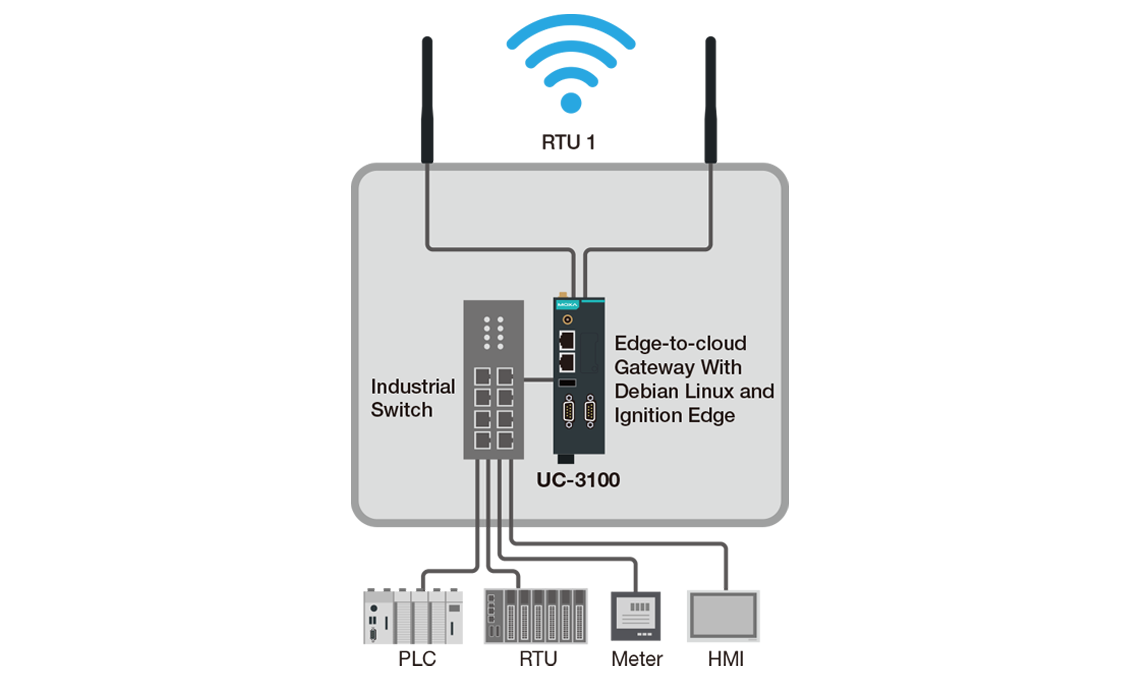

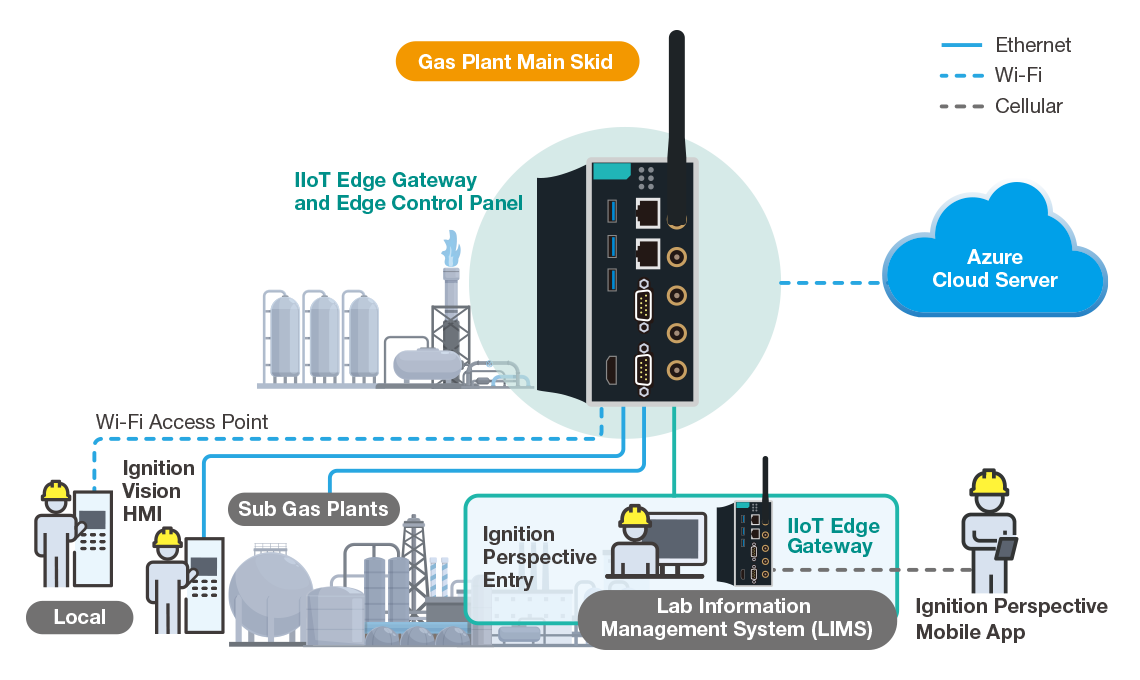

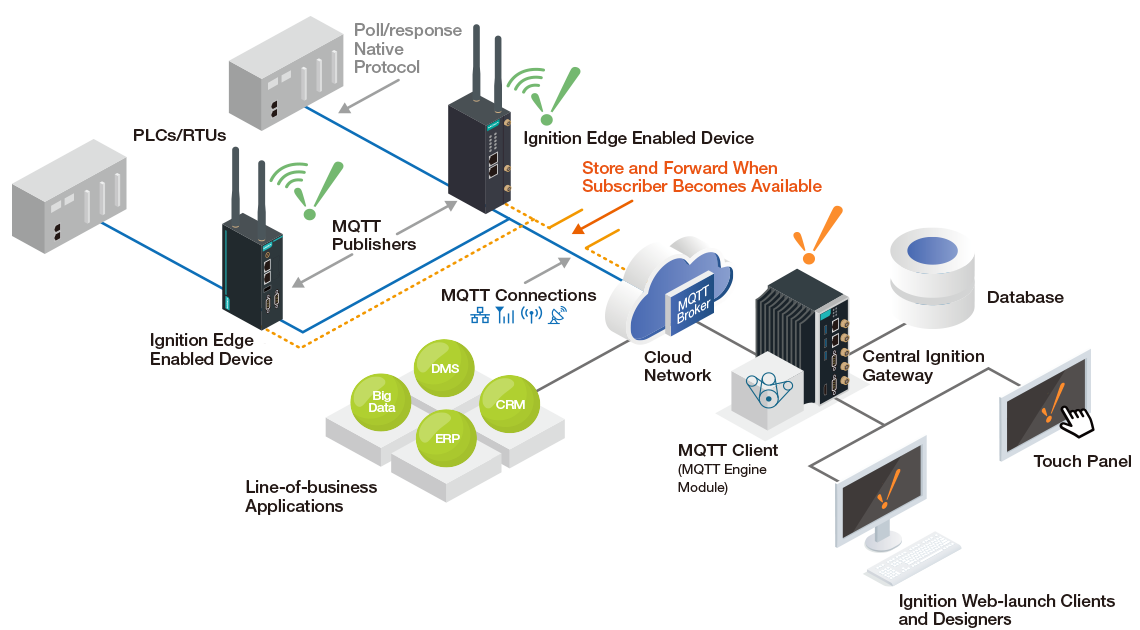

Large industrial operators with modern IoT and digital transformation objectives need to build and manage reliable unmanned connections to hundreds of devices in harsh remote environments spanning wide geographical areas. This can be especially difficult, expensive, and time-consuming if you are still using traditional proprietary solutions. Driver support from different PLC and equipment vendors can be pricey and limited. A typical edge computer and communication hardware may not be designed to withstand harsh operating conditions or recover from communication failures. Combining Ignition software with Moxa’s rugged and proven IIoT gateways and PCs provides an exceptionally reliable and cost-effective solution for PLC data acquisition with a modern MQTT or Ignition™ architecture. Inductive Automation’s Ignition offers powerful features to easily connect to most vendor devices and cloud applications, while Moxa’s products are renowned for their engineering and communication reliability, ensuring that you always have access to your critical data.

|

Power and Flexibility With Ignition

With Inductive Automation’s Ignition, you can get up-to-date driver support for Allen Bradley™, Siemens™, and Omron™ equipment and serial devices that use Modbus RTU/TCP, DNP3, OPC UA, UDP/TCP protocols, among others. You no longer need to maintain separate protocol converters or proprietary communication modules for specific devices. In addition, you get powerful and easy-to-use tools to quickly generate tags and publish the tags to an MQTT or Sparkplug™ broker.

|

|

|

|

Performance and Reliability With Moxa

Moxa’s reputation for excellence in hardware is backed by over 35 years of engineering experience in harsh and industrial environments. Our industrial IoT gateways and fanless PCs are specifically designed for the industrial edge, so they are at home alongside PLCs and other edge equipment that operate in extreme operating conditions. Board-level thermal design and low power consumption allow units to support an astonishing -40 to 70°C operating temperature range without requiring cooling fans or heaters. Our extensive range of solutions designed for multiple industries means that you will find something off the shelf that deploys quickly and works seamlessly with your software and devices.

|

|

|

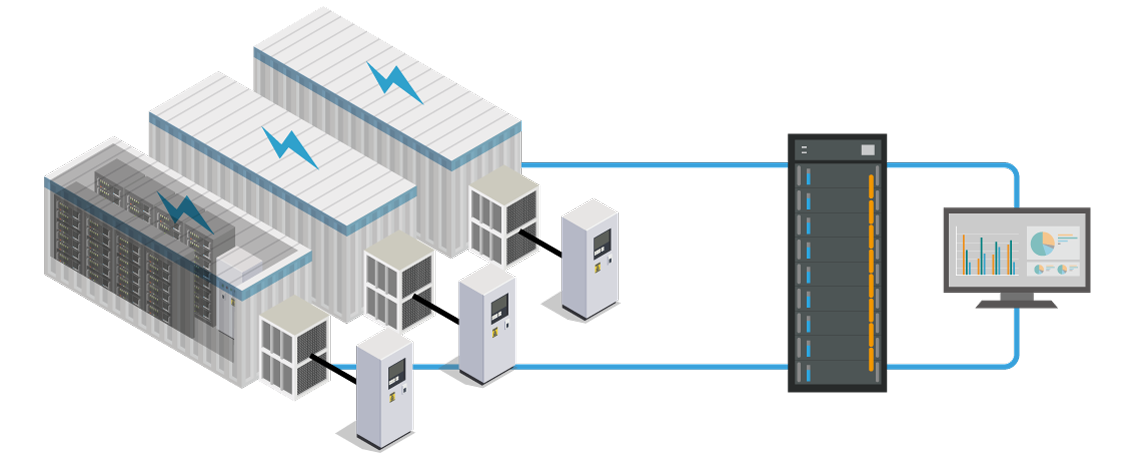

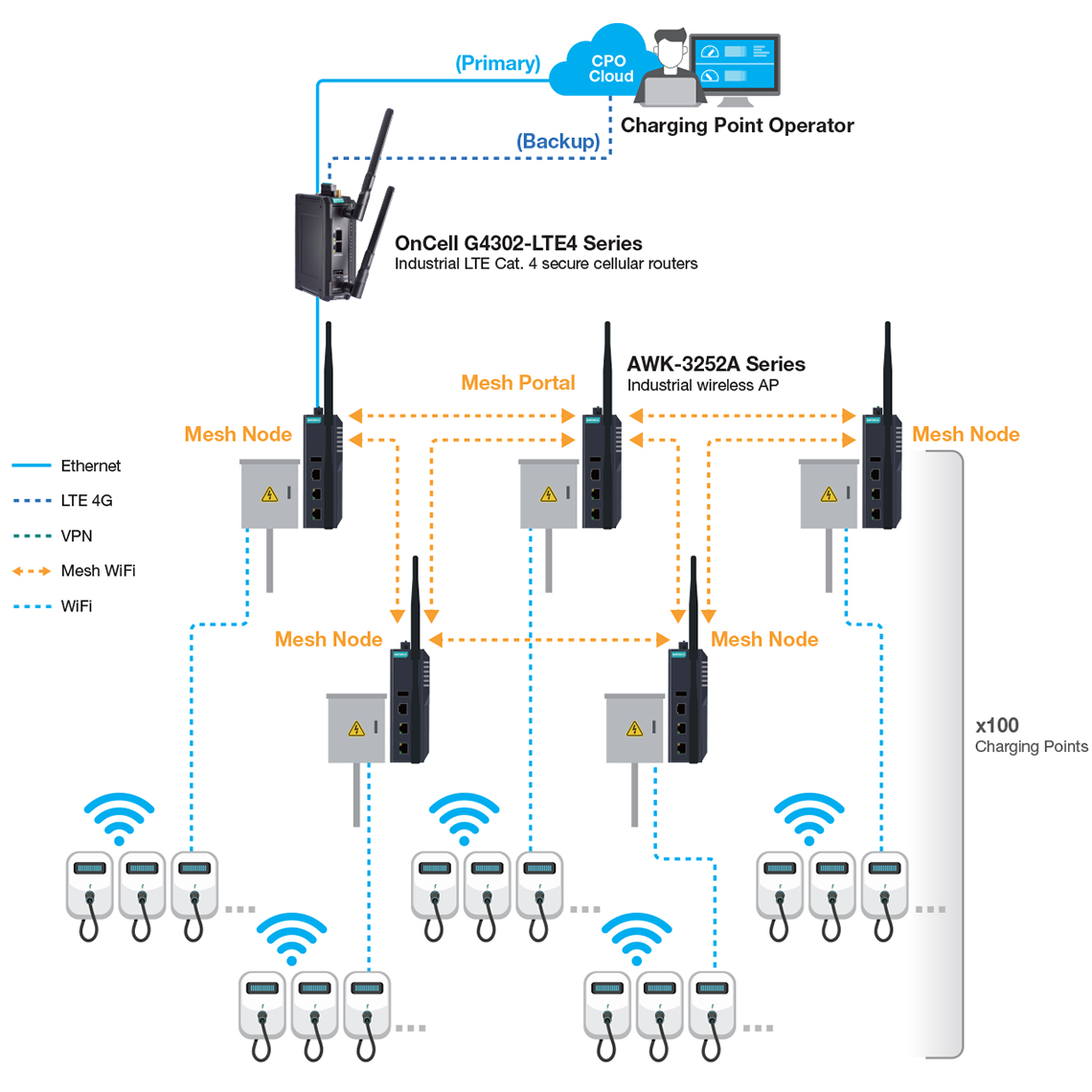

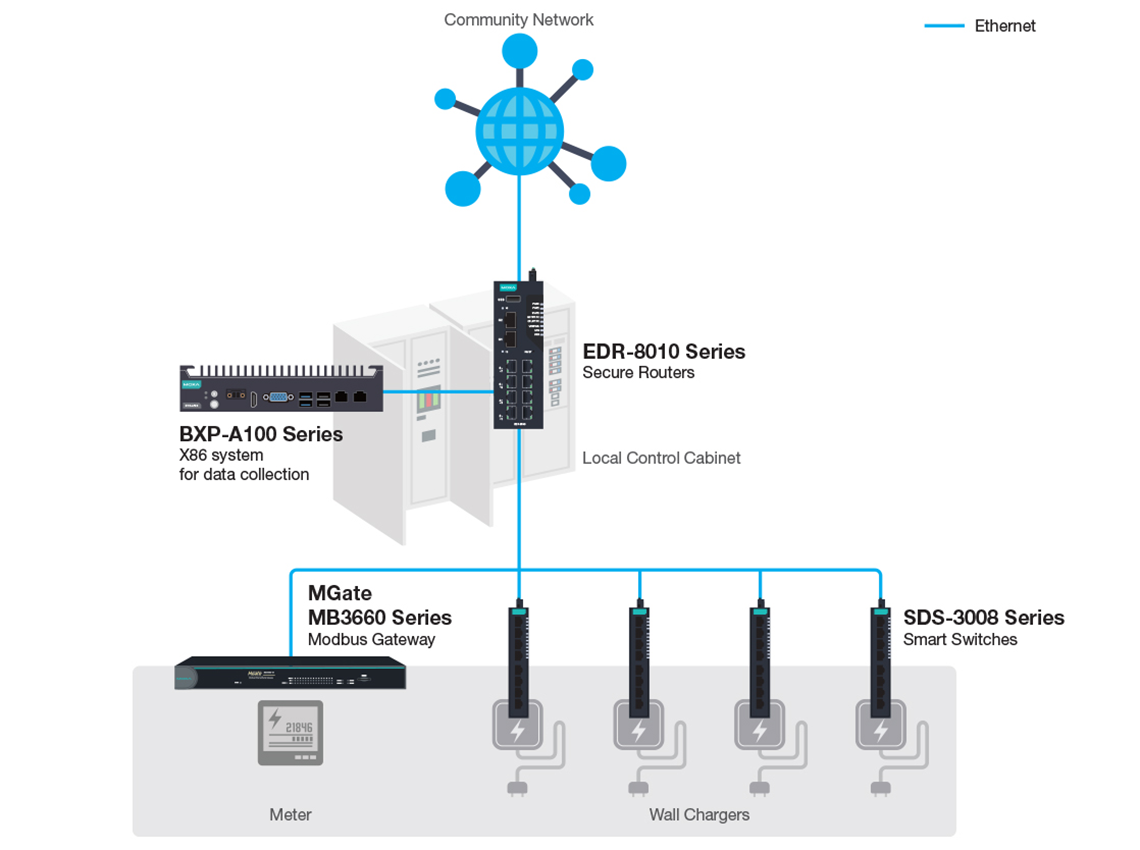

The Industrial Internet of Things (IIoT) aims to increase productivity and make users' lives easier. However, this can only be achieved when the Industrial IoT environment has reliable network connectivity. An unreliable network presents users with several challenges including longer system downtime, cyber security risks, and unstable operations, especially when using a wireless connection. The diagram below uses factory automation as an example to illustrate what kind of concerns our industry partners face when trying to adopt lndustrial loT applications and benefit from them.

BESS helps the grid stay stable by storing energy in batteries and distributing it when needed. It harnesses the advanced technologies of lithium-ion batteries, integrating them with renewable energy sources. The key elements of BESS are:

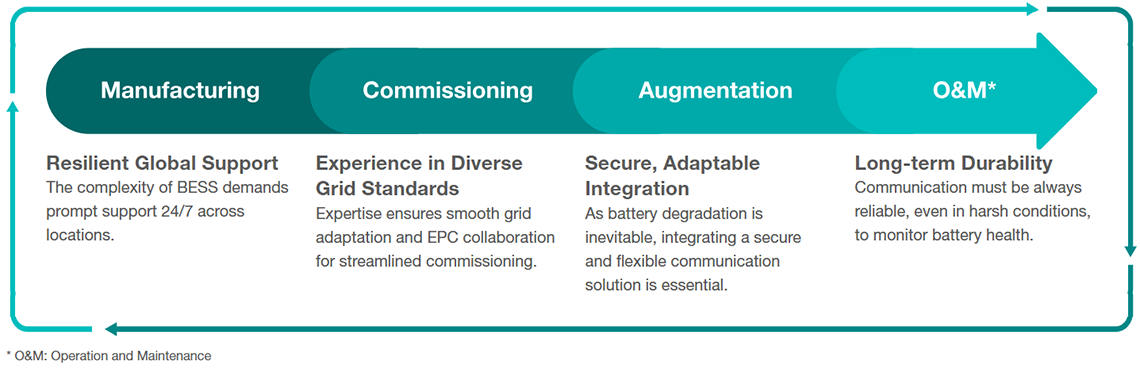

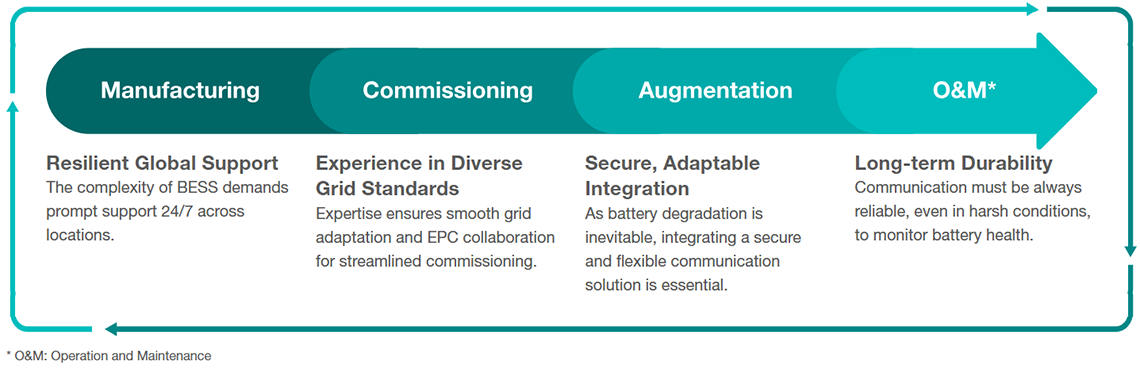

Essential Criteria for BESS Industrial Cycles

In the ever-evolving landscape of the BESS industry, navigating the complexities of its life cycle is no small feat. Addressing talent shortages, time-to-market deadlines, and futureproof planning is crucial for industry leaders. These challenges necessitate a proactive approach to overcome the unpredictability of renewable energy resources and simplify energy management.